Refurb Timber floors acoustic Performance comparison of single deck Products

This is a recently developed product and we would like to make you aware of it’s outstanding benefits when compared to other single deck acoustic floor systems:

- 22mm Flooring Grade Chipboard &

Isorubber acoustic layer combined - High density product

- Lasting Performance

- Less deflection means no floor ‘bounce’

- Laboratory and site tested

- Ideal for refurbishment of timber floors

PROBLEM foam backed boards are approximately 33% lighter

Please consider This

Please consider This

Timber floors are known to be problematic in resisting airborne sound transmission due to their lack of mass

Proven Traditional solutions

The traditional acoustic timber floor consists of a floating floor overlaying the structural deck. A typical construction consists of two 18 or 22mm wooden decks with a resilient layer between, giving a total mass of approx. 24.5Kg/m2.

Testing

The acoustic testing undertaken in the development of the Isosonic Dekfloor 30 system confirms that a similar floor mass is required to achieve a “safe” performance consistent with the Approved Doc. Part E airborne sound requirements.

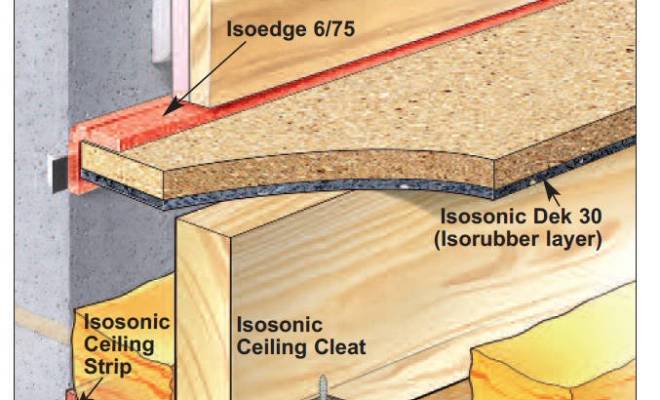

SOLUTION ISOSONIC DEKFLOOR 30

ISOSONIC DEKFLOOR 30 utilises an ISORUBBER resilient layer with a density of 910Kg/m3 giving a combined board weight of 22.5Kg/m2; just 8% lighter than the traditional floating floor. In addition the ISOSONIC CEILING CLEAT decoupling further enhances the airborne

ISOSONIC DEKFLOOR 30 utilises an ISORUBBER resilient layer with a density of 910Kg/m3 giving a combined board weight of 22.5Kg/m2; just 8% lighter than the traditional floating floor. In addition the ISOSONIC CEILING CLEAT decoupling further enhances the airborne

sound insulation.

for help choosing the right product for your project please contact Thermal economics Technical department on 01582 544255 for all our acoustic & Thermal insulation products visit: www.thermal-economics.co.uk

The development of this product has re-enforced our belief that floors of this nature require a minimum mass in order to meet the ADE airborne sound insulation requirements when used with standard ceiling and flanking treatments

Long Term Performance

It is also worth considering the performance of these products under load. A 35Kg/m3 PE/PUR foam contains approximately 97% air/gas by volume. When subjected to a normal domestic floor design load of 200kg/m2 the foam will compress by up to 30%. In the long term it undergoes further compression as the gas diffuses. This reduces its resilience and impact sound insulation properties. The acoustic testing of the unloaded floor is therefore not a true measure of its acoustic performance. ISORUBBER undergoes no discernible elastic or creep compression under normal domestic loadstherefore:

WHAT YOU TEST IS WHAT YOU GET

Benefits of Isosonic Dekfloor 30 over Pe & Pur foam backed boards

Floor Bounce

ISORUBBER also eliminates floors bouncing caused by the compression of the acoustic layer that is normally associated with foam backed boards.

ISORUBBER also eliminates floors bouncing caused by the compression of the acoustic layer that is normally associated with foam backed boards.

Isorubber is The Sound Choice

WHY NOT GET IN TOUCH? Please do not hesitate to contact our Technical Department for further information on 01582 544255

info@thermal-economics.co.uk

www.thermal-economics.co.uk